Changzhou Institute of Mechatronic Technology is a full-time public provincial higher vocational college. It was promoted to a higher vocational college in 2002 and is affiliated with the Education Department of Jiangsu Province.

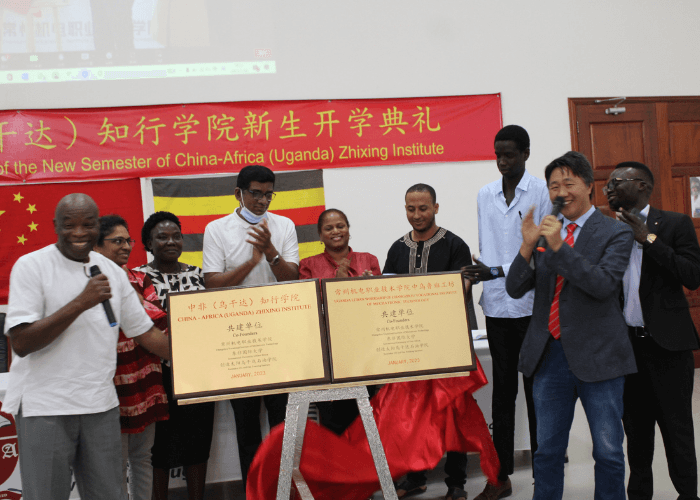

In line with the University’s vision to be the Technological University of Choice, The Partnership between IUEA and Changzhou Institute Of Mechatronic Engineering in the Faculty of Engineering and Faculty of Science & Technology will equip its students with CNC Machining knowledge.

What is CNC Machining

In short, CNC machining is a metal fabrication method where written code controls the machinery in the manufacturing process. The code determines everything from the movement of the cutting head and the part to spindle speed, RPMs, etc.

What the students will gain

The students who will be part of the program will be awarded a diploma by IUEA as well as the Changzhou Institute Of Mechatronic Engineering, also for those who will perform exceptionally well will be given an opportunity to go to China for an internship at the Changzhou Institute.

“CNC Machining comes as a game changer to the manufacturing industry in Uganda equipping students with hands-on experience”

Said the Vice Chancellor, Prof Emeka Akaezuwa while addressing the media

How do CNC Machines work?

Modern CNC machines are fully automated. They need digital files with instructions about cutting trajectories and tooling.

Design or machining processes require many tools to produce a specific part, Machinists can build digital tool libraries that interface with the physical machine such machinery can automatically switch tooling based on the digital instructions, making them manufacturing workhorses.

Lastly, the software determines the nesting. Nesting means the orientation and placement of parts relative to raw material. The purpose is to maximize Material usage.

All this information is then translated into codes that the machinery can understand – M-code and G-code.